Technical Parameters

Contact us

Custom non-standard automation equipment

Current location:HOME>LM-1235 Automatic Lens Mounting Machine

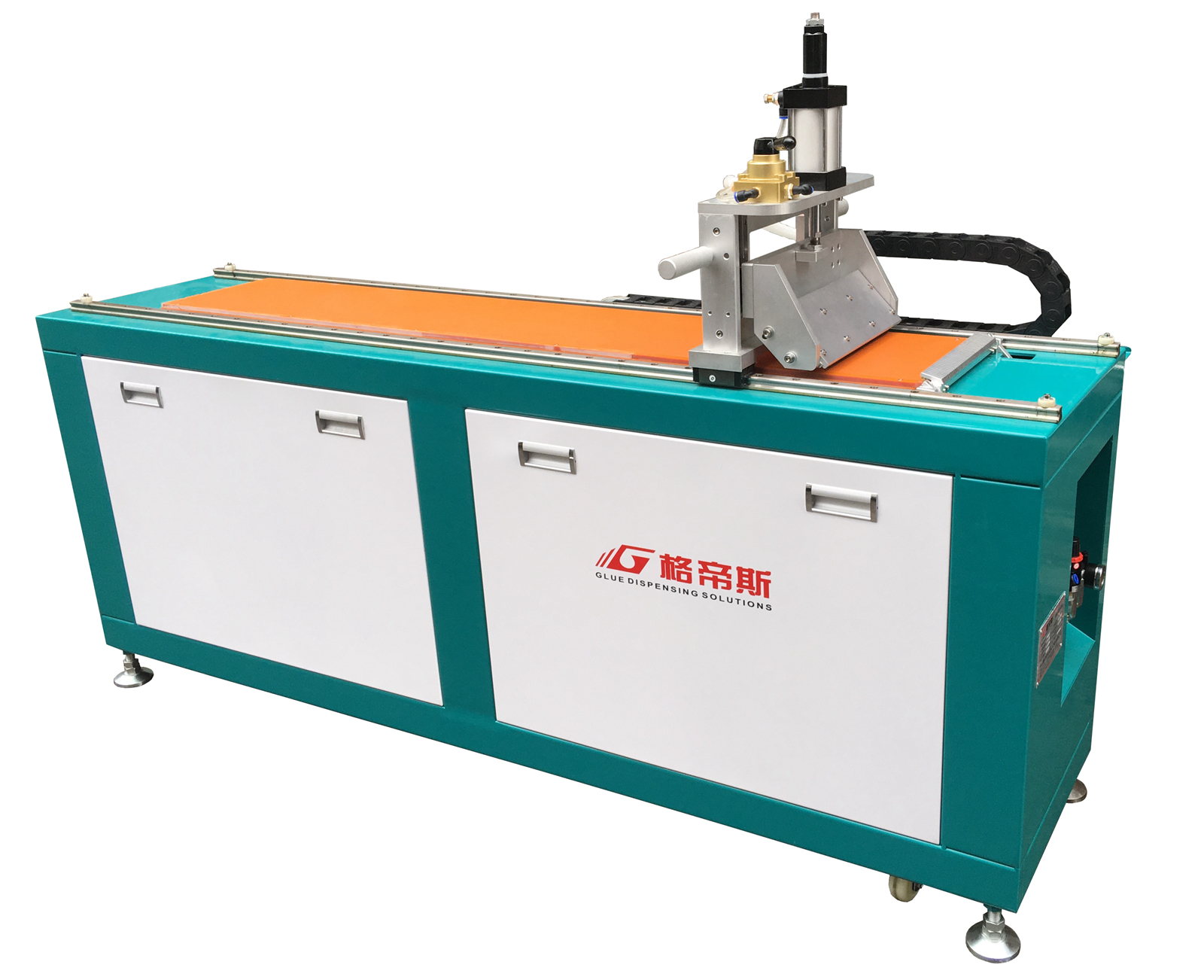

LM-1235 Automatic Lens Mounting Machine

Principle Description

Optical lens are filtered and delivered via vibration disk to mounting position of PCB board. At the same time, PCB board is placed on the cross sliding platform. The platform move as programmed. When PCB board moves to the

- Product introduction

- Technical Parameters

- Video display

Principle Description

u Optical lens are filtered and delivered via vibration disk to mounting position of PCB board. At the same time, PCB board is placed on the cross sliding platform. The platform move as programmed. When PCB board moves to the mounting position, lens is sucked up and pressed down, then mounted to positioning hole accordingly.

Machine Feature

u Specially designed for lens mounting of wall washer or linear light;

u Designed capacity is 3000 points/h, actual capacity is above 3000points/h;

u Different design of lens require different customisation of vibration disk

u PLC+movement control board+touch screen is equipped, easy to learn and operarte;

u Gluing function can be integrated to realise lens gluing and mounting at the same time

Suitable Glue:

Silicone, thermal conductive silicone grease, UV glue, AB glue,etc

Applications:

LED wall washer,linear light, etc.