Technical Parameters

Contact us

Back-lit Panel Light Solution

Current location:HOME>TC-60 Back-lit Panel Glue Dispensing and PCB Fixing Machine

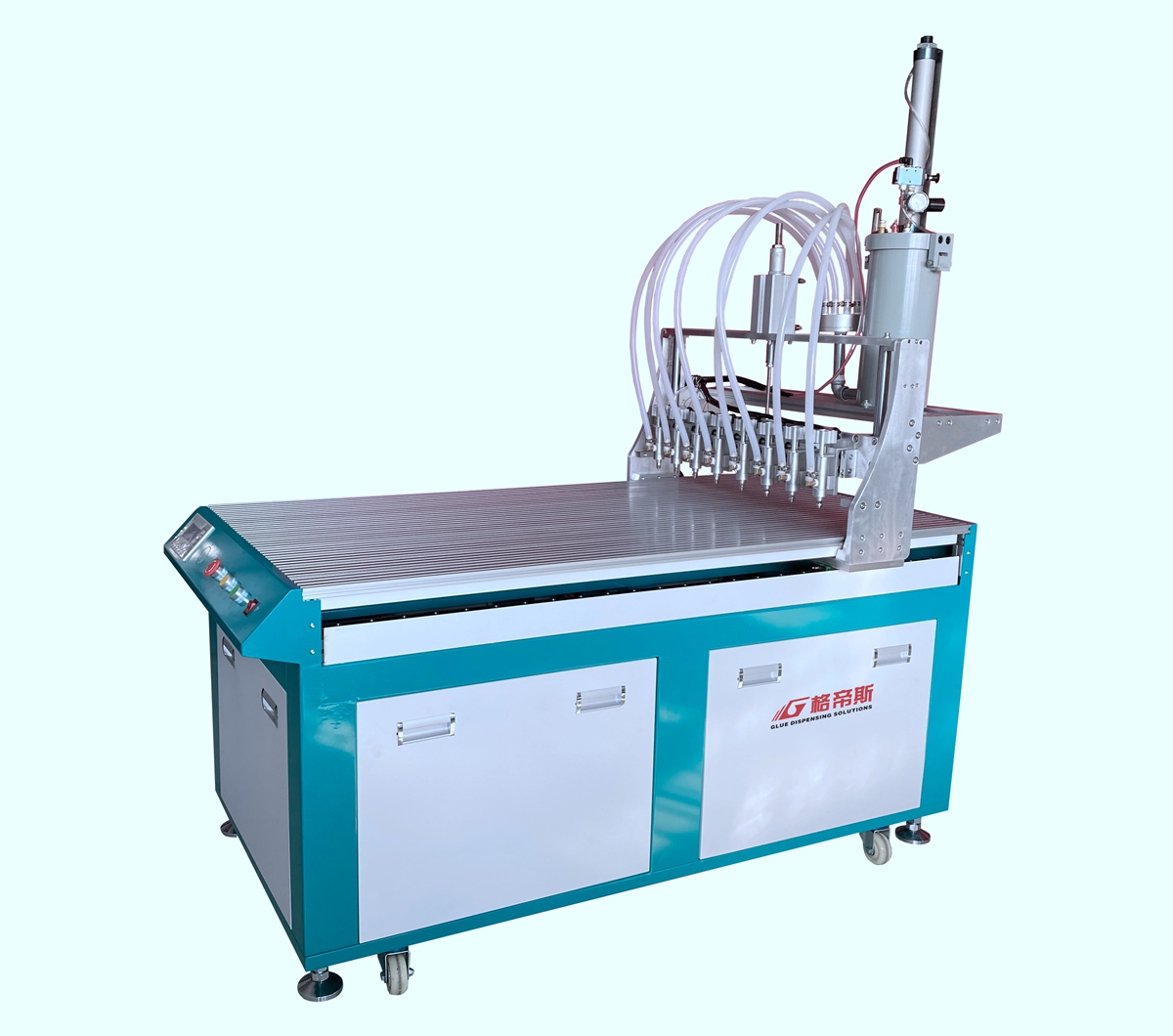

TC-60 Back-lit Panel Glue Dispensing and PCB Fixing Machine

Principle Description

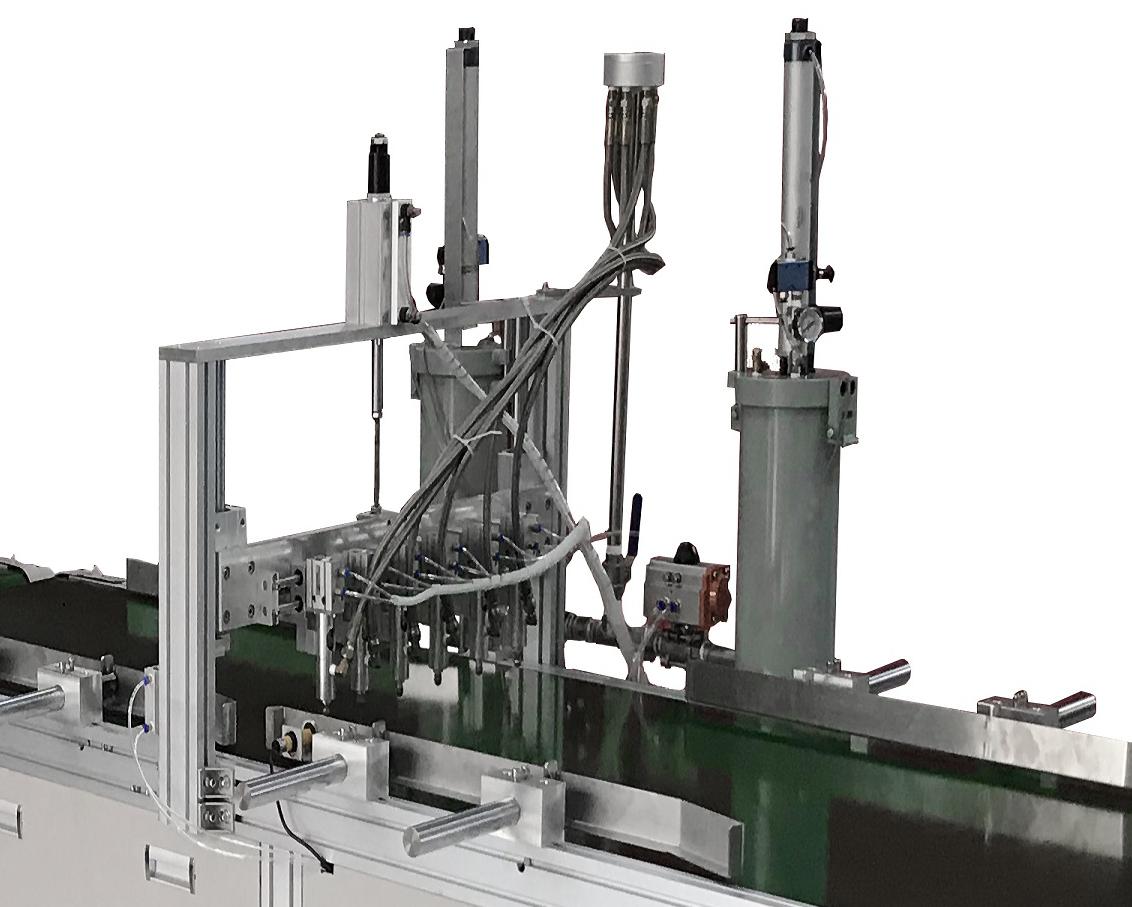

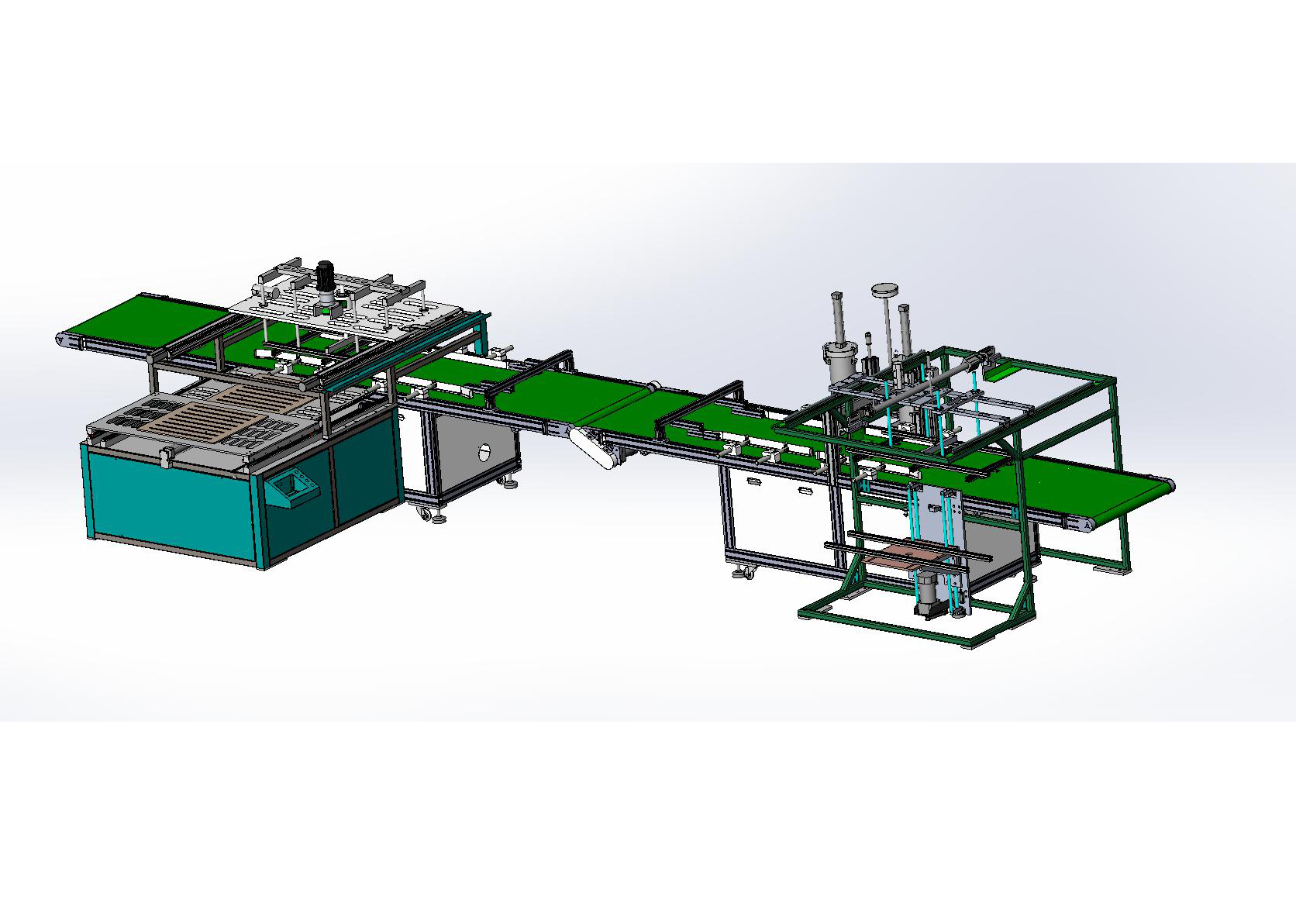

Machine is equipped with multiple glue dispensing heads according to panel light design. The glue dispensing system starts to dispense glue on the board when it reached the position.The pane board will be well glued while it’s movin

- Product introduction

- Technical Parameters

- Video display

Principle Description

Machine is equipped with multiple glue dispensing heads according to panel light design. The glue dispensing system starts to dispense glue on the board when it reached the position.The pane board will be well glued while it’s moving forward. After gluing, it will be brought to the next PCB fixing station. PCB strips are placed on the fixture manually and will be sucked up and brought to the top position of glued panel board, then pressed down, PCB strip fixing done. Panel board will flow to the next assembly station or be piled up.

Machine Feature

u Specially designed for back-lit panel light gluing, and PCB strip sticking

u Designed capacity is about 300pcs/h(600*600mm panel)

u Movement control +PLC, touch screen UI, easy to learn and operate

u Speed adjustable conveyor transfer, matching worker operation speed ;

u Conveyor can fit for different size of panel light;

u Work-piece sensor available, automatically activate the glue valve, no need to press start button frequently;

u Glue valve can be controlled independently. Glue flow is fast and accurate;

u 2600ml big glue pot feeding, no need to change the glue package frequently

Suitable glue: 2600ml package silicone application: Back-light Panel