Technical Parameters

Contact us

Back-lit Panel Light Solution

Current location:HOME>TC-6060 Back-lit Panel Double-station Gluing and PCB Fixing Machine

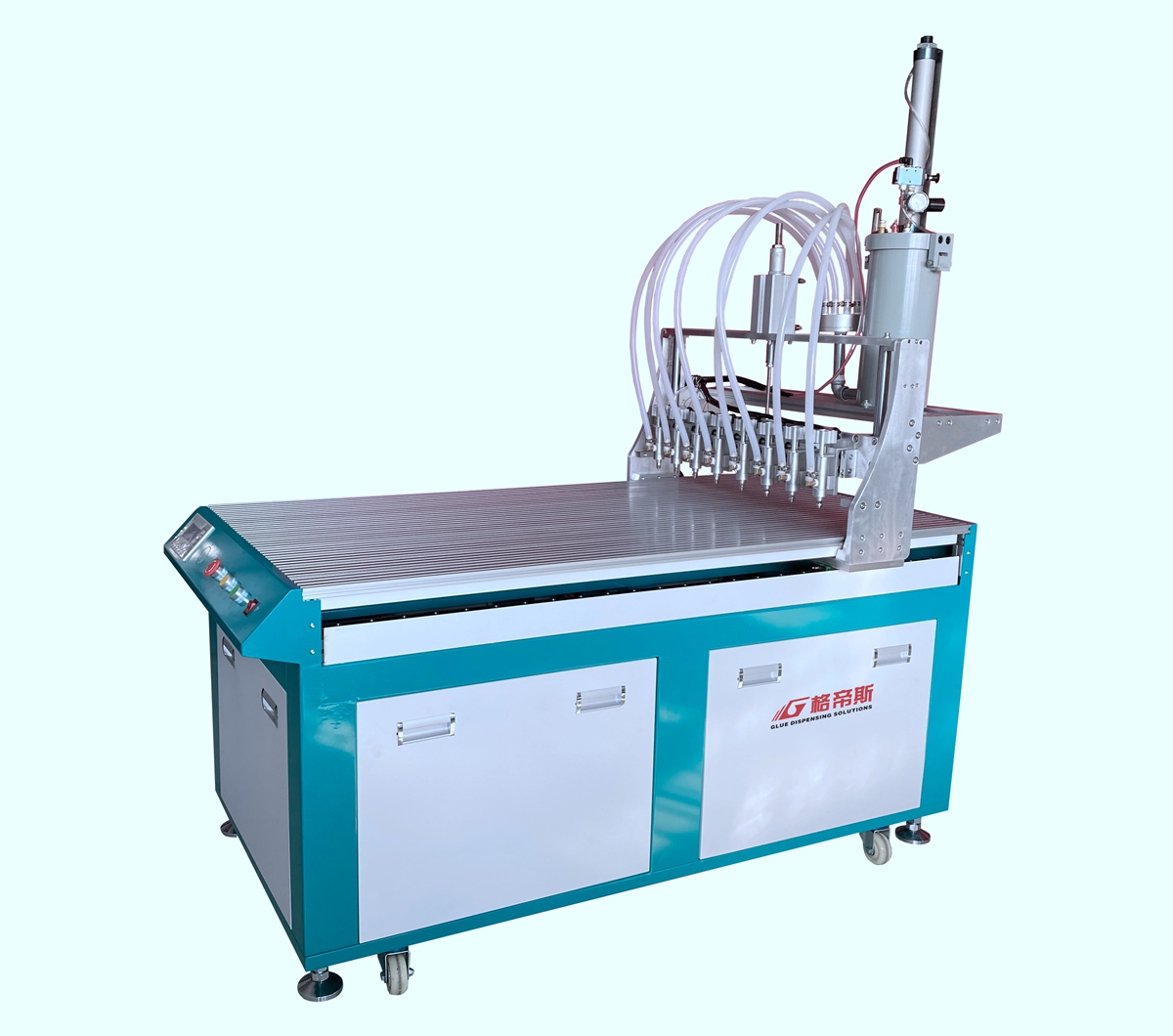

TC-6060 Back-lit Panel Double-station Gluing and PCB Fixing Machine

Principle description:

Two operators standing at each side of the machine. One is responsible for putting the PCB strips on the fixture board (lens downside), press “start” button. The fixture board will move forward, during which glue dispensing valve o

- Product introduction

- Technical Parameters

- Video display

Principle description:

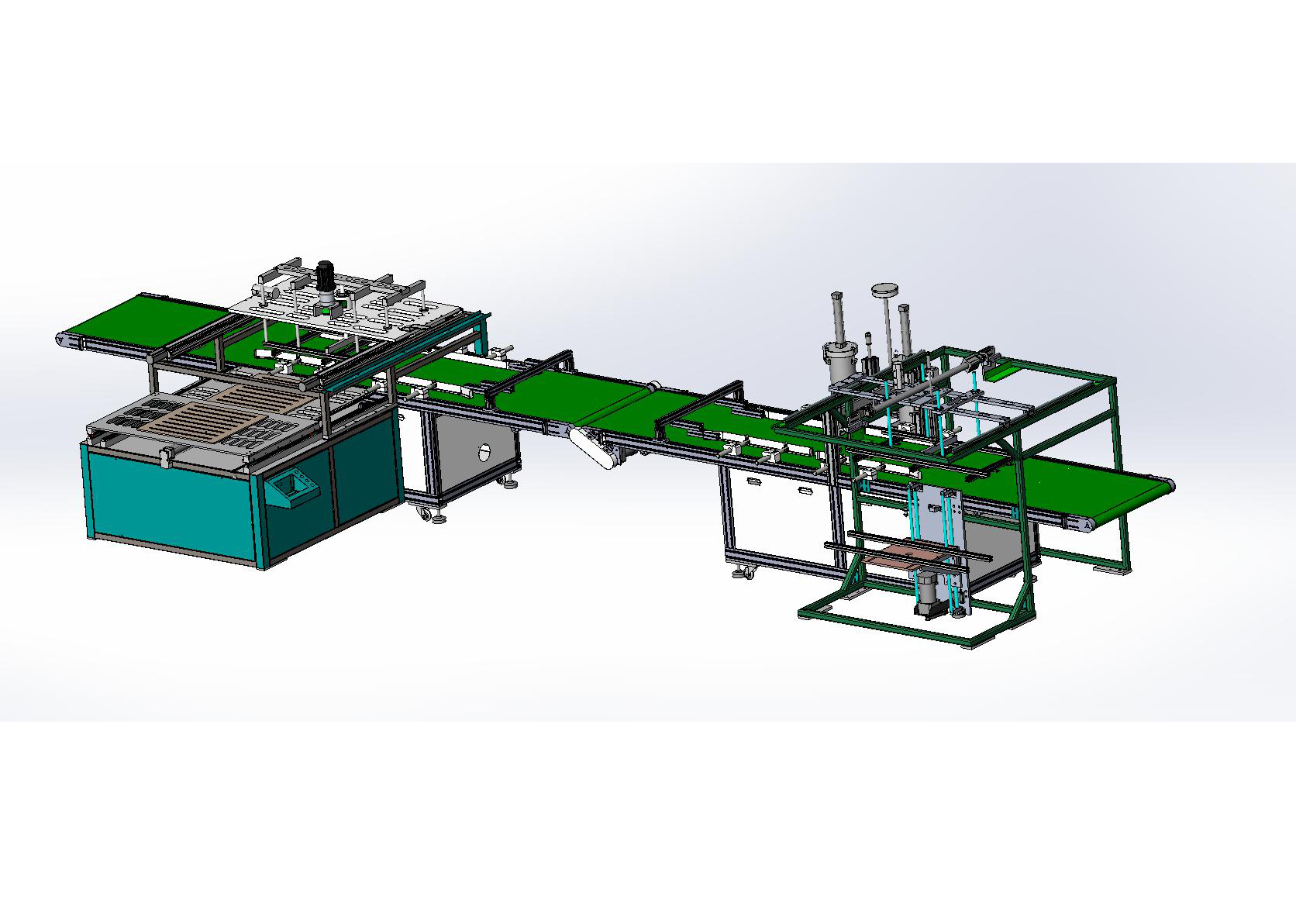

Two operators standing at each side of the machine. One is responsible for putting the PCB strips on the fixture board (lens downside), press “start” button. The fixture board will move forward, during which glue dispensing valve open, glue is applied on the PCB strips in good uniformity. While finishing gluing, the fixture board arrived at the other end, where the operator can put the panel board upside down on the glued PCB strips, then press it a little bit. The PCB strips and panel board connect together perfectly. Press the “reset” button, the fixture board will go back to the original point, start another shift. Two station design on each side to work in cycle, greatly improve the work efficiency.

Machine features:

l Specially designed for back-lit panel PCB gluing and fixing

l Equipped with multiple glue dispensing heads, two glue container feeding system, accelerate the feeding speed and reduce glue bottle change frequency

l Glue flow is fast and even, glue dispensing head moving speed is adjustable

l Two work station design to work in cycle, no need to waste time waiting, improve work efficiency

l capacity:250-300pcs/h (real capacity depends on glue viscosity, raw material quality, operator experience etc.)

l PLC + touch screen control, easy to learn and operate

Parameters:

|

Model |

TC-6060 |

|

Main control unit |

PLC |

|

program |

Touch screem |

|

drive mode |

Stepping motor |

|

working range |

600*600mm |

|

positioning accuracy |

±0.2mm |

|

weight |

300Kg |

|

dimension |

165*200*185CM |

|

power |

AC220-380V/50~60Hz/ 3000W |

|

pressure |

0.4 ~ 0.6Mpa |

|

working tempreature and humidity |

temperature:0 ~ 40℃ humidity:20 ~ 90% |

Applicable glue: 2600ml package silicone

Applications:LED back-lit panel